Coatings & Linings

Industrial Solutions USA provides coatings and cast elastomeric linings that are formulated for the “toughest” physical properties to protect our customer’s assets from the destructive elements of UV, corrosion, chemicals, abrasion and impact. Our formulations have been proven in the lab and in the field.

Our coating & lining formulations have been selected because they exhibit the most robust physical properties of the competitive formulations on the market.

- 100% solids (no VOCs) linings and cast elastomers.

- High density cross-linked coatings.

- Aliphatic and aromatic base coatings and top coatings.

- Removable coatings.

- High temperature coatings.

- Iron phosphate conversion coating.

Applications

UV Resistance

- Clear aliphatic polyurethane/polyurea hybrid coating loaded with UV absorbers.

- Formulated to work with existing new or highly oxidized paint systems, fortifying those systems and providing 10 years added protection.

- Additive available to reduce gloss.

- Additive available to create a “tough” very hydrophobic coating that releases the buildup of graffiti, ice, swarf, concrete, slurry, dirt and grime.

Corrosion Protection

- Highly cross-linked monolithic coatings protect valuable above ground storage tanks, pipelines, equipment and facilities from expensive corrosion.

- Constant and intermittent immersion service, splash zone protection.

Removable Protective Coating

- Elastomeric one component thick coating that seals the substrate surface from water, chemicals, dust and debris providing protection against corrosion, abrasion, UV and impact.

- Simply apply then peel off when the asset is to be put into service or an inspection is required.

Iron Phosphating Conversion Coating

- Unconventional deep penetrating conversion coating that deposits a protective iron phosphate coating and and microcrystalline barrier directly on the metal substrate eliminating the corrosion cell – stopping further corrosion.

- Safe and easy to use.

Abrasion/Impact Resistance

- Softer durometer thick cast and sprayed on linings protect valuable equipment from the wear and tear of processing materials, material handling and environmental forces.

- Cast lining pads are excellent high-impact absorbers.

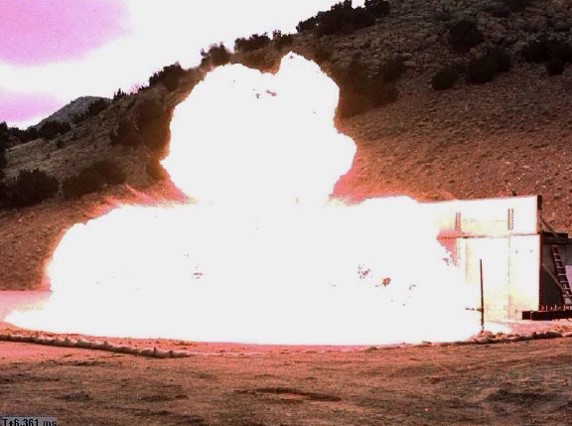

Blast Mitigation

- Mitigate the destructive forces of collisions and explosive blasts. Test reports are available upon request.

Fire Resistance

- Thick non-halogenated monolithic barrier to fire. Adjust the thickness of the lining to accommodate fire temperature and velocity.

- The intumescent char is tenacious and remains flexible. Tests have proven the char will not ablate under moderate to heavy fire velocities (please contact us for specific test results).

Non-skid Surfaces

- Coatings – moderate non-skid surface

- Linings – moderate to very aggressive non-skid surface